As an animatronics supplier that has produced over 1000 dinosaur models, we are intimately familiar with the production of creating a large animatronic dinosaur. To exaggerate, our workers could create any kind of dinosaur, even if they were blindfolded.

In short, the animatronic dinosaur production process is nothing more than these 7 steps: 1. welding the mechanical steel structure, 2. rust prevention treatment and wrapping it with high-density sponge, 3. carving the dinosaur shape on the sponge, 4. then heating the skin textures on the sponge, 5. evenly applying silicone to create elastic skin, 6. spraying realistic or cartoon skin colors, and 7. testing the final product.

Here we explain in detail how to create a large animatronic dinosaur (12 meters long animatronic Carnotaurus style as example).

Information Board:

#1. Welding the mechanical steel structure

#2. Rust prevention treatment and wrapping it with high-density sponge

#3. Carving the dinosaur shape on the sponge

#4. Heating the skin textures on the sponge

#5. Evenly applying silicone to create elastic skin (silicone skin-grafting)

#6. Spraying realistic or cartoon skin colors

#7. Testing the final product

1. Welding the mechanical steel structure

Animatronic Carnotaurus Mechanical Structures

Our mechanical workers will shape about one ton of steel into the form of a dinosaur (Carnotaurus). They used tools such as cutting machines, welding machines and welding rods to transform the channel steels and steel pipes into a steel dinosaur-shape frame structure.

After the steel structure is completed, our electrical engineers will install the motors at the mechanical transmission positions. The motors with appropriate power are installed according to the dynamic range of the dinosaurs and the load-bearing capacity of the steel frame.

Finally, our workers will apply a coat of anti-rust paint on the already galvanized steel to prevent the entire dinosaur-shaped steel frame from rusting in the humid climate.

The tools used:

5 welding machines with a power of 1000W

120 pieces of welding rods

1 cutting machine

1 gantry crane

The materials used:

1 ton of steel or so

10 large springs

3 250W motors

2 450W motors

2 150W motors

2 80W motors

5 kilograms of industrial butter

2. Rust prevention treatment and wrapping it with high-density sponge

Wrap Sponge for Animatronic Carnotaurus

After completing the work of mechanical structures, the workers need to carry out rust prevention treatment for the entire steel framework. The steel used for welding the steel frame was all galvanized. Through this works, the internal steel will not rust even after being exposed for over 20 years.

After that, our workers will attach density standard 40 foam to the mechanical framework. This type of foam has a high degree of softness and stretch elasticity, and will not cause resistance to the mechanical transmission parts.

The tools used:

2 sculpting knives

2 rulers

The materials used:

20 kilograms of yellow glue

5 ten centimeters thick sponge

3 three centimeters thick sponge

1 one centimeters thick sponge

3. Carving the dinosaur shape on the sponge

Sculpture Animatronic Carnotaurus

Our sculptors will use the carving knife🔪 to make head, mouth, body, muscles and tail of the Carnotaurus out. All were meticulously carved to be extremely lifelike. Generally, our sculptors have over three years of technical experience and can create the exact and lifelike shapes of all kinds of dinosaurs.

The tools used:

1 sculpting knife

1 ruler

The materials used:

3 kilograms of yellow glue

1 three centimeters thick sponge

After our sculptors complete the dinosaur shape, they will fill in the holes that were left on the dinosaur’s body.

4. Heating the skin textures on the sponge in soldering iron

Heating Skin Textures of Animatronic Carnotaurus

Creating the skin texture of dinosaurs is as meticulous a job as painting. Our workers need to hold soldering irons and, following high-definition pictures of dinosaur skin textures, carefully create the skin patterns stroke by stroke.

The dinosaur skin textures can roughly be divided into two patterns: one resembling the cracked bark of a tree, and the other featuring spots like those on a turtle shell.

Dinosaur Skin Textures – Cracked bark of a tree

Dinosaur Skin Textures – Spots

4 soldering irons

1 sculpting knife

The materials used:

2 kilograms of yellow glue

1 one centimeters thick sponge

5. Evenly applying silicone to create elastic skin (silicone skin-grafting)

Animatronic Carnotaurus Silicone Skin Works

Once the Carnotaurus model skin patterns are completed, a layer of highly elastic silicone needs to be applied to cover it as its “clothing”. Usually, our workers will evenly apply three layers of silicone on the entire body of the dinosaur model and attach high-fiber stockings to enhance flexibility. Finally, a layer of silicone mixed with gasoline was applied to make the skin of the entire dinosaur body smooth and fine.

The dinosaurs with silicone skin grafts had high elasticity and would not cause resistance to the internal mechanical movements.

2 water ladles

8 hairbrushes

4 glue guns

The materials used:

150 kilograms of silicone

25 kilograms of silk stockings

4 scissors

35 kilograms of gasoline

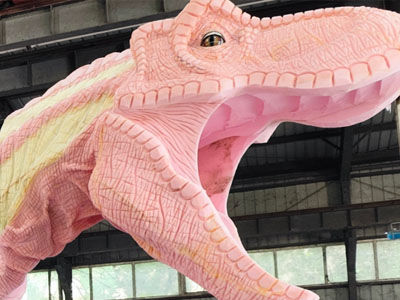

6. Spraying realistic or cartoon skin colors

Painting Animatronic Carnotaurus Skin Colors

Painting Animatronic Carnotaurus Skin Colors

After applying a layer of “silicone coat” to the dinosaur model, our dyeing workers will begin the task of spraying on the dinosaur’s skin colors. The process typically involves pouring a mixture (gasoline, silicone, and oil paint) into a spray gun and then spraying it onto the dinosaur to recreate its skin colors, much like painting.

Create two styles of dinosaur skin tones: Lifelike dinosaur skin and cartoon dinosaur skin.

Lifelike Dinosaur Model

Cartoon Dinosaur Models

1 air compressor

1 spray gun

20 meters long PU air pipe

The materials used:

15 kilograms of gasoline

6 kilograms of silicone

0.5 kilogram of oil paints

7. Testing the final product

Once all the manufacturing processes for the 12 meters long animatronic Carnotaurus are completed, our electrical engineers will be able to test its dynamics.

Engineers will use the customized CPU control box to activate the dinosaur’s movements (eye blinking, mouth opening and closing, tail moving left and right, claws moving, etc.) and run it continuously for 5-8 hours to confirm that the product is free of problems and ready for shipment.

How to operate an animatronic dinosaur >

What should we do if a problem is discovered?

- Quality inspectors will report the situation.

- Upon receiving a report of a malfunction, the relevant personnel will immediately follow up and resolve the issue.

Summarize

The above seven production steps help us create the most exquisite lifelike dinosaur models (animal models), making us a leader in the animatronics industry. If you need animatronics models, please contact us for the best products.