Zigong City in China is a remarkable place, serving as a global industrial base for manufacturing animatronics models. Nearly 80% of all animatronic dinosaurs are produced here. Of course, this is also the birthplace of our company (Universal Dinosaurs), where there is a super cool dinosaur-themed production company with over 15 years of experience.

After many years of development, we have significantly improved our industrial production techniques, focusing mainly on manufacturing more advanced animatronics models. The main advancements lie in the improvement of mechanical structural materials, the application of servo motors, and the extensive use of environmentally friendly silicone materials. This enables our products to be superior to those of our competitors.

Information Board:

#1. More advanced mechanical structural materials

#2. More environmentally friendly rust prevention paint treatment

#3. Use more advanced servo motors / engines

#4. More efficient and stable control box

#5. Use Standard-50 density sponge for shaping

#6. Weather-resistant silicone to work skin grafting

#7. Strict and responsible quality inspection department

#8. The movements are not only smoother but also more dynamic

1. More advanced mechanical structural materials

Update Animatronics Structures

Over the past three years, we have extensively used galvanized steel structural materials to replace the original cast iron materials. Galvanized steel has a stronger resistance to corrosion, and can be exposed outdoors for over 20 years without rusting. The animatronics internal structure made of galvanized material significantly enhances its durability and also makes it look more advanced.

Advantages of galvanized steel:

- The anti-corrosion strength is more than ten times stronger than that of ordinary steel, basically preventing the steel from rusting.

- Due to the enhanced rust prevention function, the internal structure has become more stable, and its durability is at least 20 years or more.

- This makes the internal components of the animatronics models have a more technological appearance.

2. More environmentally friendly rust prevention paint treatment

Anti-Rust Handle

The previous anti-rust paints had extremely strong acidity and a strong odor, which could cause certain physical harm to the people who came into direct contact with them. However, over the past five years, we have switched to environmentally friendly anti-rust paint. Not only does it not have any irritating smell, but it also does not have any impact on the environment.

Advantages of galvanized steel:

- The zinc content exceeds 80%

- When mixed ith the curing agent, it will dry within half an hour

- The primer has a stronger adhesion. Even if you gently scrape it with a scraper, the paint won’t come off

- Applying it onto the galvanized steel surface can enhance the rust prevention performance by more than twice

- The rust preventive paint used is the same as that used for the internal components of marine vessels to prevent rust

3. Use more advanced servo motors / engines

Previously, we mostly used ordinary wiper motors to create the internal dynamic structure! Although the motor has stable efficiency, its movement is mechanical and rigid, and its dynamic range is limited. On the road of development, we have been seeking more advanced motors that can support larger dynamic amplitudes. After years of development and experimentation, we gradually use servo motors (more high-tech industrial motors to replace the previous wiper motors).

What are the advantages of servo motors / engines?

- The control accuracy is even higher.

- Response speed is faster and the speed adjustment range is wider.

- Higher overload capacity and more stable torque control.

- Better stability and a longer service life.

- The efficiency is 50% higher than that of ordinary motors.

Mechanical structure made with servo motors – Video demonstration:

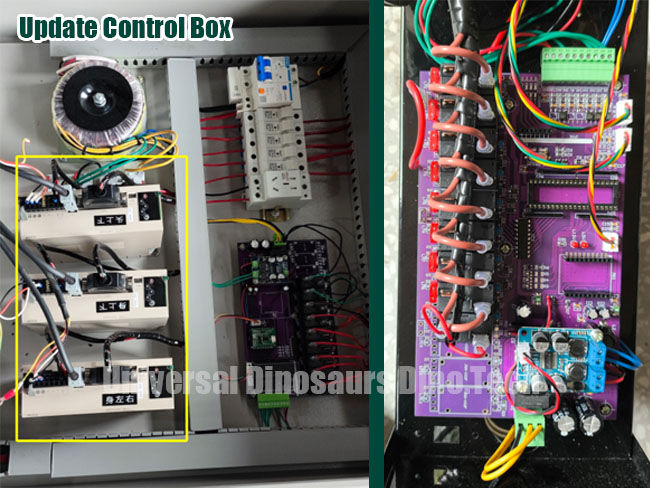

4. More efficient and stable control box

Update Control Box

The control box is the CPU processing system of our animatronics model! The stability of the subsequent dynamic operation and the guarantee that the electrical appliances will not malfunction all depend on it. Since we have mostly replaced the traditional motors with servo motors, we need to update the electrical system inside the old control box.

What internal systems have been updated?

- Each model’s movement is customized with a small powered smart device, which is equivalent to adjusting the previously rigid movements to a smoother amplitude.

- The internal voltage equipment has been increased, the load of electrical control has been increased, and the control box can be operated in high temperature and cold climates.

5. Use Standard-50 density sponge for shaping

Sculpture Oviraptor Outline on the Foam

In order to increase the service life of the animatronics model, we used sponge with standard-50 density when shaping its body! That is, a sponge that can resist external impact with high strength and will not be easily stretched or broken. The use of the sponge can not only extend the model’s life, but also increase the dynamic range of animatronics model.

What are the advantages of this sponge?

- Good supporting performance: The 50-degree high-density sponge can provide stable support for the items it carries, keeping the shape of the items unchanged, and is suitable for situations where higher support force is required.

- Strong durability: Due to its high density, this sponge has high compressive resistance and can maintain good elasticity during long-term use, extending its service life.

- Good moisture-proof performance: The 50-degree high-density sponge has smaller fiber gaps, which can effectively block moisture intrusion and is suitable for humid environments, keeping the material dry and comfortable.

- Easy to clean: The fiber gaps on the surface of high-density sponge are small, and stains are not easy to penetrate, so it is easy to clean and maintain, keeping the material neat and beautiful.

- Environmentally friendly and non-toxic: This material complies with environmental protection requirements, does not contain harmful substances, is harmless to the human body and the environment, and is safer and more reliable to use.

NOTIFICATION: Based on customer requirements, we can also use fire-resistant sponges to create the bodies of animal models.

Using high-density sponges to sculpt the body – Video demonstration:

6. Weather-resistant silicone to work skin grafting

Silicone Made Skin for Dinosaur Model

In order to extend the life of animatronic models, we also had to use weather-resistant silicone to make the dinosaur / animal skin! The skin work is usually made by applying three layers of silicone, which can be waterproof, snowproof, and sun-proof.

Advantages of climate-resistant silicone:

- It can effectively isolate water from invading the internal steel frame structure.

- Silicone can dry up in less than half an hour to improve the efficiency of our skin making.

- Flame retardants can be mixed in to give it a certain fire resistance.

- Between high temperature of 50°C and low temperature of -30°C, it can effectively insulate and allow the internal electrical appliances to run smoothly.

7. Strict and responsible quality inspection department

Quality Inspection

When our animatronics models are completed, they must pass the quality inspection department before they can be allowed to be shipped. Our quality inspection department must ensure that the model runs with zero failures before it is shipped. We will never leave any problems to customers to solve.

hanks to our responsible quality inspection department, our global customers are extremely satisfied with our products.

Quality inspection process after product completion:

- First, power on the electric model, and our electrician will observe the dynamics for more than 10 minutes and listen to whether there are any abnormal sounds from the internal machinery.

- If there is no abnormal noise, let the model run continuously for 4-6 hours to see if there are any problems with the status after a day of work.

- If there are no problems on the first day, the quality inspection department will run it for 3 consecutive working days. If there are still no problems, they will sign to certify that the product can be shipped.

NOTIFICATION: If any problem is found in any of the above steps, our electrical engineers will solve it immediately and will not leave any hidden trouble.

8. The movements are not only smoother but also more dynamic

Because of the support of the servo motor inside, the movement range of the finished model is increased. Visitors were stunned to see that dinosaurs could not only roar and turn their heads, but also pitch their bodies forward and roar, and sway from side to side… Such animatronics models not only exceed the exhibition expectations of entertainment venues, but can also reach the exhibition level of more high-end science and technology museums.

Summarize

The above eight points are the state of our more advanced animatronic animal models! Such the models no longer only have rigid mechanical movements, but can also make movements that are more in line with the dynamics of real animals. This is definitely the model product you need more.